The main focus of the work is on a detailed understanding of the pyroelectric properties (PE) in thin doped HfO2 layers. Pyroelectric properties were characterized for various doped HfO2 and Hf1-xZrxO2 films with different thicknesses.

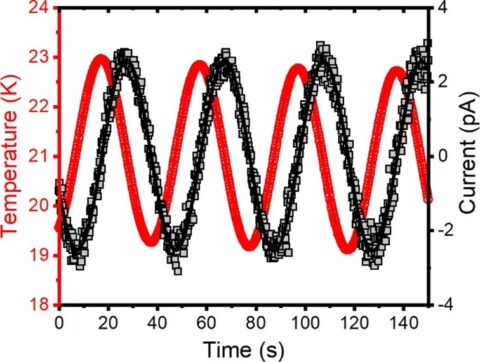

A survey of the pyroelectric behavior was undertaken for a wide variety of dopants incorporated into HfO2 including Al, Gd, Sr, and La as well as the Hf0.5Zr0.5O2 composition. In addition to understanding the effect of different dopants, a detailed investigation of the pyroelectric dependence on the Si-concentration in Si-doped HfO2 thin films was carried out to evaluate the influence of the doping concentration on the pyroelectric performance. The Sharp-Garn method detects the current response upon a sinusoidal temperature stimulation was used to accurately determine the pyroelectric coefficients in ferroelectric films. Infrared sensing applications for example require a linear and reversible transduction of temperature into electrical charge (Fig. 1).

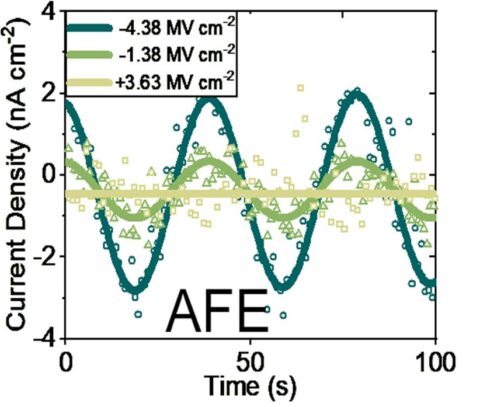

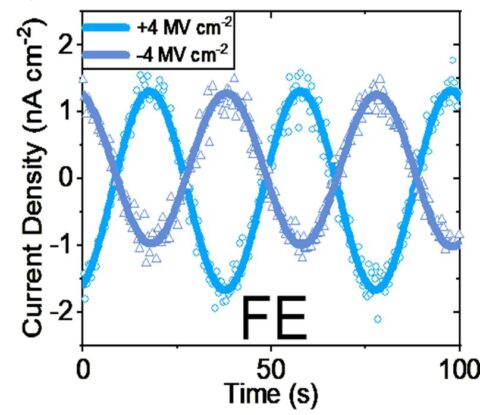

A new pyroelectric device was developed that incorporated antiferroelectric Hf-doped ZrO2 within a work function (WF) engineered capacitor, where electrode materials of TiN and RuOx were used to generate a constant internal electric field. This innovative development not only produces a zero applied field (passive) pyroelectric response from antiferroelectric thin films, but it also enables non-volatile on/off switching of the pyroelectric effect via bipolar voltage pulses. To distinguish and quantify the pyroelectric properties of ferroelectric Hf0.5Zr0.5O2 and WF-engineered ZrO2 thin film capacitors, both the poling and film thickness dependence was investigated. The pyroelectric coefficient in Hf0.5Zr0.5O2 was found to exhibit an electric field poling dependence due to the different polarized states of the ferroelectric films, whereas in the WF-engineered antiferroelectric ZrO2 capacitor the pyroelectric coefficient can be set either to -90 or 0 µC K-1 m-2 depending on the polarity of the poling field (Fig. 2).

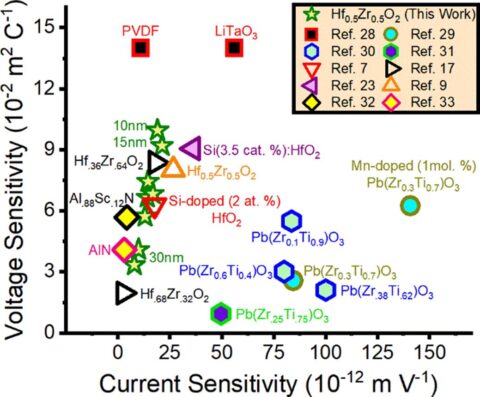

With strong pulsed poling fields, the pyroelectric coefficient saturates by maximizing the remanent polarization induced in the ferroelectric films. The role of film thickness was determined by varying Hf0.5Zr0.5O2 films from 10 – 30 nm in thickness. The highest pyroelectric coefficients and best figures of merit were obtained in 10 – 15 nm Hf0.5Zr0.5O2 thin films annealed at 450 °C (Fig. 3),

whereas the pyroelectric performance in thicker films and higher annealing temperatures was degraded due to the formation of the monoclinic phase and low-k interfacial layers. Through the Landau-Devonshire Gibbs energy equation for ferroelectrics, a relationship between the dielectric, ferroelectric, and pyroelectric properties was established in all types of HfO2-based thin films by the Curie constant.

Cooperation:

RWTH Aachen (Germany), Hochschule München (Germany), Oak Ridge National Labs (USA), TU Bergakademie Freiberg (Germany)